The plant is equipped with highly technical machinery and testing equipment’s like Tensile Testing Machine, Hardness Tester H R B, Hardness Tester H R C, Spectrometer, Conductivity miter with Display, Hardness Tester etc.

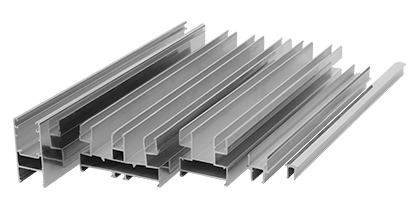

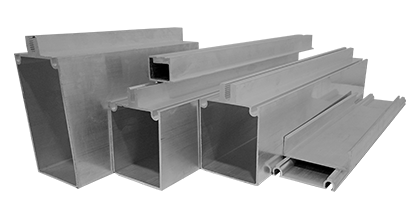

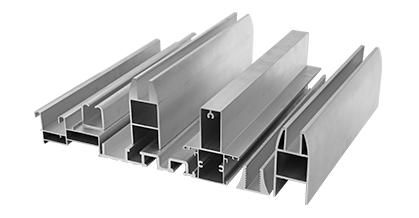

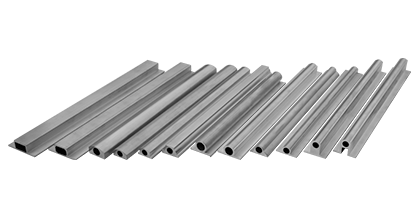

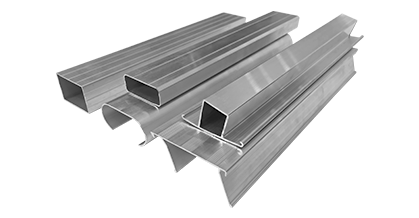

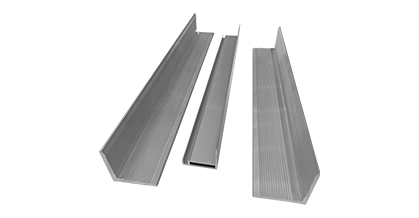

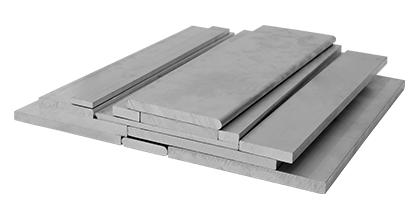

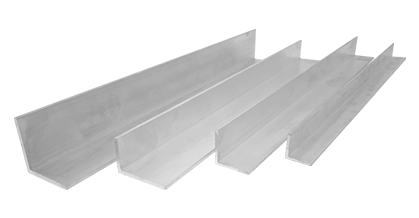

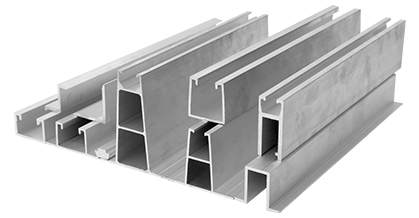

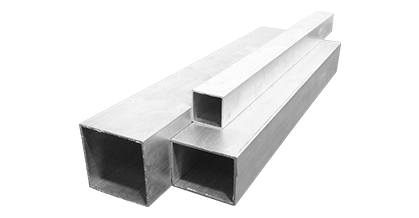

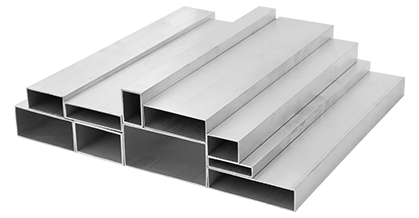

Aluminum extrusions have many excellent properties such as low weight, good electrical & thermal conductivity, strength corrosion resistance, formability, machinability, design possibilities etc., and above all, can be recycled, therefore offering high value in numerous applications.

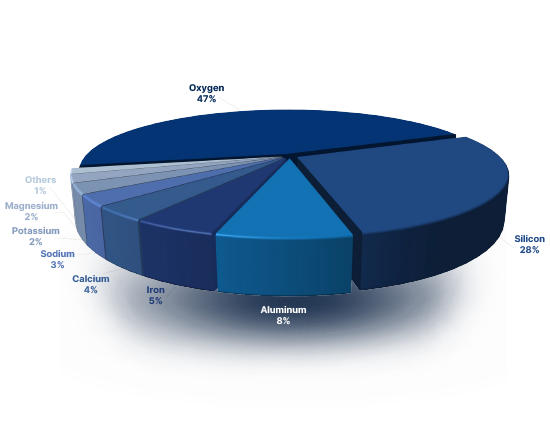

Aluminum is one of the most commonly found elements on the surface of the earth. With nearly 8% of the Earth’s crust constituting this metallic element, it is safe to say that it is available almost everywhere.

A light metal, aluminum is significantly advantageous as it is possible to restrict the environmental impact while working with it. It is due to these reasons that those looking to minimize the ecological impact of a project look at aluminum over other materials. What’s more? The metal is wear-resistant, difficult to corrode, reducing significant maintenance costs and improving business productivity. Further, it is also more efficient to transport as it has less weight.

Quality Control

The company adheres to stringent quality norms for all the processes. The materials used by Vinitech Metal are of very high quality and compatible to the latest machinery and production process. The company’s technical and commercial quality guidelines are set to high standards.

A team supervises the quality assurance and control aspects along with the entire process system by identifying and associating with the quality circle. Quality control Tests are conducted regularly to maintain a uniform product quality.

Value Addition

Anodizing is the electrochemical process provides additional protection aside from the natural oxide film. A durable, porous anodic oxide layer is formed on the surface of the aluminum. Anodized aluminum will also accept vibrant colors. We can anodize any kind of aluminum product. This Coating is desirable due to following properties:

- Increased corrosion resistance

- Increased durability / wear resistance

- Ability to be colored through dying

- Electrical insulation

- Excellent base or primer for secondary coating

Anodizing Process

Step1

Step2

Step3

Step4

Step5

Step6

Step7

Step8

Step9

Step10

Step11

Step12

Step13

Step14

Step15

Step16

Step17

Step18

Step19

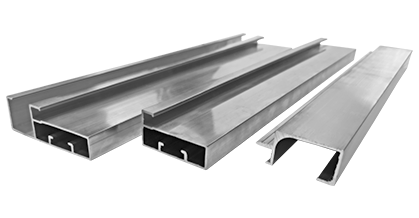

Packaging

Vinitech Metal has always believed that customers should be given prime importance and all products should meet their requirements. This ideology is also practiced in the packaging process of the finished product. All products are packaged as per customer’s requirements and only then dispatched.

So keep sections and their surfaces safe during transportation, we can provide interleaving with paper, polythene, stretch film, bubble sheet and cardboard as required. Wooden box and pallets can also be used when transport distances and sections sensitivity demand. Bundles are also made to facilitate manual loading/unloading.